Chemical Compatibility Table for Bottle Mouth Disp

Release time:

2024-08-20

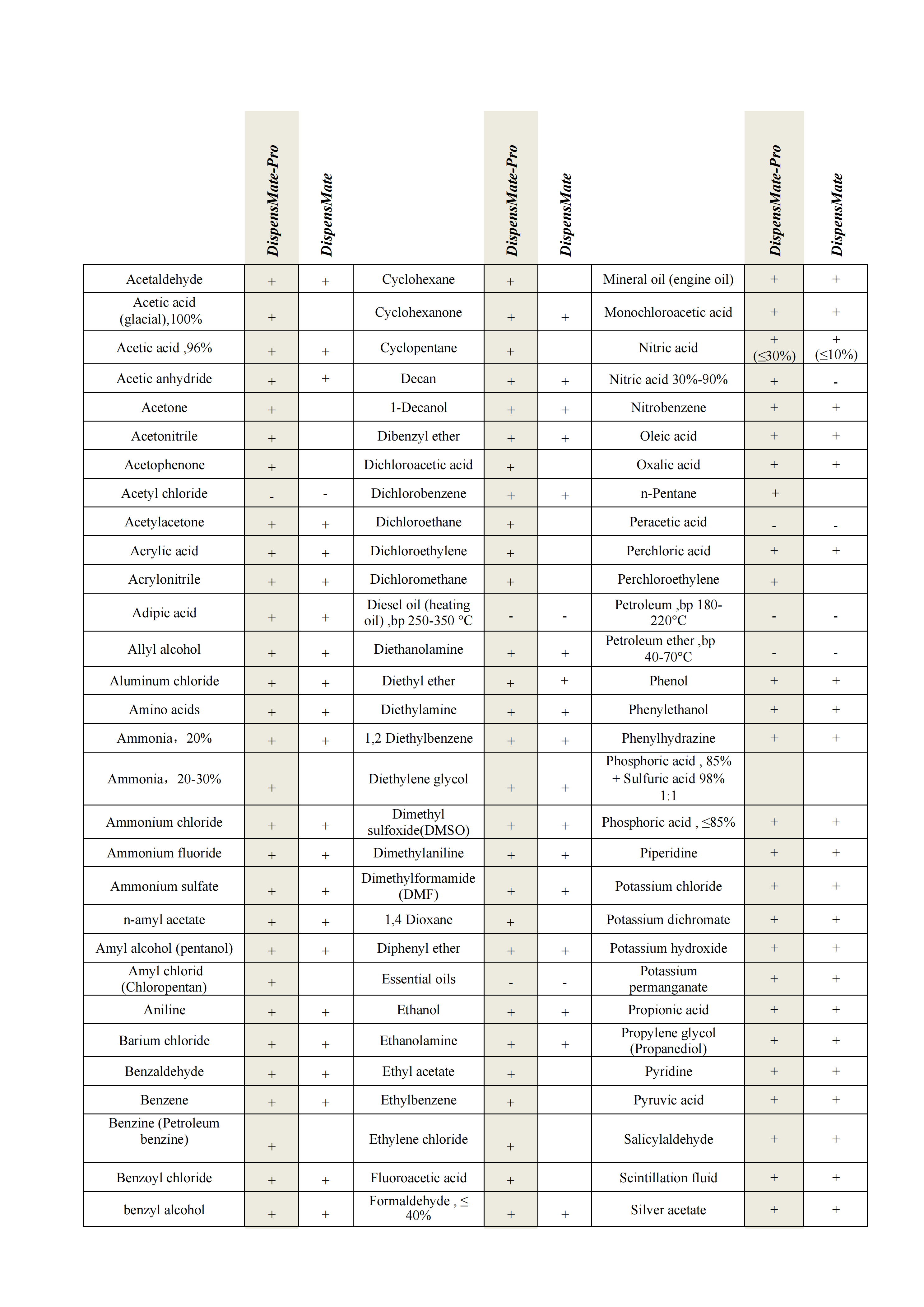

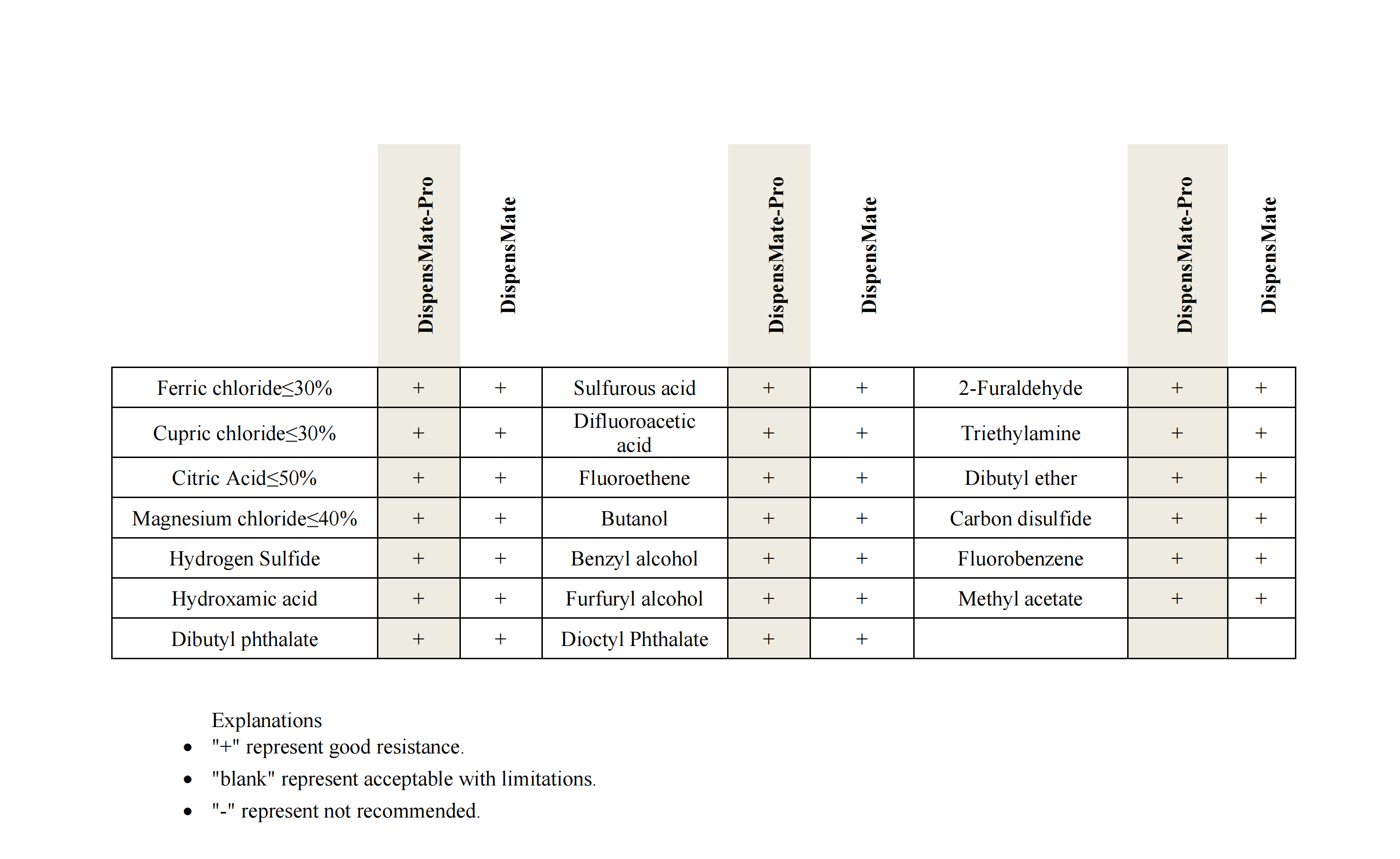

The devices of DLAB-DispensMate which contact with dispensed liquid consist of BSG, PTFE, FEP, and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials. The devices of DLAB-DispensMate-Pro which contact with dispensed liquid consist of BSG, PFA, PTFE, FEP, ETFE, PVDF and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials.

DispensMate Dispenser Chemical Compatibility at 20℃

The devices of DLAB-DispensMate which contact with dispensed liquid consist of BSG, PTFE, FEP, and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials.

The devices of DLAB-DispensMate-Pro which contact with dispensed liquid consist of BSG, PFA, PTFE, FEP, ETFE, PVDF and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials.

Please notice the table is just a directional guide not the manufacturer's commitment. Please read the user manual carefully before use and to do related experiments can necessarily which can be used to determine whether should be used. Good laboratory practice would be to rinse out the liquid handing unit at the end of each day with distilled water to prevent

corrosive liquids being left in contact with the parts for too long.

Version:0.9

StartHTML:0000000105

EndHTML:0000004007

StartFragment:0000000141

EndFragment:0000003967

Notes:

1. Hydrochoric acid – in the presence of oxidising may cause slight attack on prolonged boiling.

2. Sulphuric acid – will dull the surface with prolonged heating at above 250°C.

3. Dispensmate-pro dispenser with specifications of 0.5-5mL / 1.0-10ml /2.5-25mL is not suitable for sulphuric acid (98%) removal. Specifications of 5-50mL /10-100mL Dispensmate-Pro bottle mouth dispenser is suitable for sulphuric acid (98%) removal.

4. Nitric acid (fuming) – may dull the surface with prolonged heating.

5. Phosphoric acid – may dull the surface with prolonged heating.

6. Potassium hydroxide – the fused salt will cause slight attack.

7. Sodium hydroxide – the fused salt will cause slight attack.

8. Hydrogen peroxide 30% - in the presence of hydrochloric acid may cause slight attack on prolonged boiling.

9. Ammonia – heating in an ammonia atmosphere will darken and dull the surface, leading to a porous crystalline appearance.

10. Chlorine – in the presence of hydrochloric acid may cause slight attack on prolonged boiling.

11. Potassium permanganate – in the presence of hydrochloric acid may cause slight attack on prolonged boiling. 12 Sodium carbonate – the fused salt may cause slight attack.

12. Mercury – will readily attack at any temperature.

13. Silver nitrate – the fused salt may cause slight attack and discolour the surface.

14. Organic compounds - most organic compounds on the market do not have corresponding data, please do a preliminary test

Keyword:

Next

Help Topics

Are you still confused about what type of stirrer

An appropriate stirrer can give full play to the advantages of overhead Stirrer, significantly shorten the mixing time and provide the best mixing effect. DLAB Overhead Stirrer provides a variety of stirring tools, such as Vane Stirrer、 Propellar Stirrer、Radial-flow Stirrer、Anchor Stirrer. There will have a choice for your need.

Guide for selection of magnetic stirrer bars

Guide for selection of magnetic stirrer bars

The type of centrifuge rotor is introduced

Fixed Angle rotor refers to a fixed Angle between the central shaft of the centrifugal tube and the rotating shaft, most of which is between 14 and 45 degrees. The larger the Angle, the better the separation effect. The advantages of this rotary head are low center of gravity, balanced operation, and can quickly collect sediment. However, when the particles settle, they will hit the centrifugal tube along the centrifugal force direction, and then slide along the tube wall to the bottom of the tube, forming precipitation. The wall effect is easy to cause strong convection in the tube, affecting the separation effect.

Daily maintenance and calibration of pipette

a. After each experiment, the scale of the pipette gun should be adjusted to the maximum so that the spring can return to the prototype to extend the service life of the pipette gun. b. Pipettes with liquid suction should not be placed flat: the liquid in the head can easily contaminate the inside of the gun and may cause the spring of the gun to rust. c. When setting the range, please be careful to rotate until the required range number is clear in the display window, and the range set is within the range of the pipette. Be careful not to rotate the button out of the range, otherwise it will jam the mechanical device and damage the pipette.

Chemical Compatibility Table for Bottle Mouth Disp

The devices of DLAB-DispensMate which contact with dispensed liquid consist of BSG, PTFE, FEP, and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials. The devices of DLAB-DispensMate-Pro which contact with dispensed liquid consist of BSG, PFA, PTFE, FEP, ETFE, PVDF and closure cap of outlet is PP; non-contact liquids parts consist of PC and other materials.